Article: Avantor's Claudia Berron discusses "Raw data: A 4.0 Approach to Materials Offers Process Development Benefits"

Webinar: Digitalizing biopharma: How raw material data can maximize biopharma supply chain and manufacturing practices

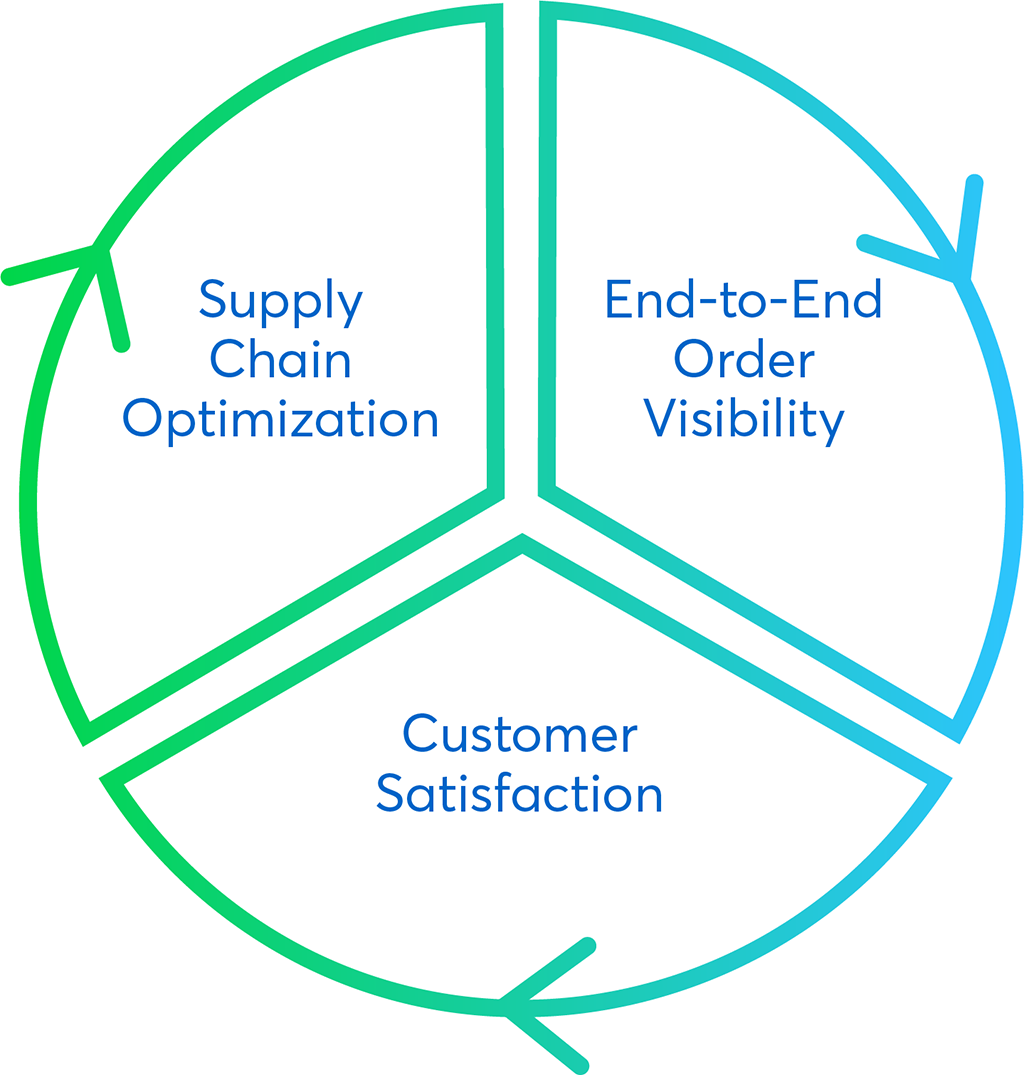

Scientific workflows rely on access to trusted, high-quality products to produce traceable, repeatable results. SmartScience digital services focus on optimizing the supply chain for trusted products customers need for their workflows. Our Supplier Central platform speeds onboarding efficiency of supplier products onto our global e-commerce channel, where customers leverage full visibility into product availability, end-to-end ordering and fulfillment. Similarly, SmartScience provides a connected digital experience where access to raw material data can facilitate supplier collaboration serving the evolution of product traceability standards needed within the biopharmaceutical industry.

SUPPLIER CENTRAL – SPEEDING PRODUCT TIME-TO-MARKET

Before science can bring novel therapeutics to market, an entire supply chain of product must be made easily and readily available. SmartScience facilitates this process through Supplier Central, a platform dedicated to expediting onboarding, management and ongoing marketing of supplier products. Supplier Central helps speed time-to-market of essential products and provides end-to-end order visibility within a digital platform where suppliers:

- Leverage the reach of our global e-commerce platform, with local relevancy and access with more customer touchpoints.

- Manage data and content, such as product additions and line extensions, as well as improved product visibility with the product enrichment process.

- Stay informed and organized, with easy access to current Avantor sales channel initiatives through monthly e-newsletters, as well as download logos and process steps to efficiently work with Avantor team members.

- Plan media by learning about advertising opportunities for better campaign planning.

DIGITALIZING BIOPHARMA: INCREASING VISIBILITY OF RAW MATERIALS

As biopharmaceutical manufacturing continues to evolve, SmartScience solutions can help facilitate the collaboration between biopharmaceutical manufacturers and raw material suppliers at the forefront of “biopharma 4.0” using Artificial Intelligence (AI), big data and smart technologies to help transform the existing business model.

In biopharma production, the smallest variation in even a well understood and characterized raw material, such as a buffer, can have a detrimental effect on the entire process. Our customer-centric approach, and decades of experience working with our biopharma customers, has given us the opportunity to collaborate and find better, more efficient, solutions to this production challenge.

Robust data about the full characterization of raw materials used can narrow down, and even pinpoint, root causes of the variation and help trace them back to a specific raw material. SmartScience applies this data gathering model, combined with robust analytics, to streamline the process of finding the cause of an irregularity and over time, even help to predict and prevent future occurrences.

Avantor’s rich history of collaboration supports the idea of gaining in-depth visibility from suppliers through collaborative efforts. This would give biopharma manufacturers the ability to trace the journey of their raw materials and identify potential risk. Detailed data about characteristics, packaging, storage and handling would help producers more accurately assess and predict the process performance of any given raw material – ahead of its use.

With supplier collaboration, available datasets could be leveraged across the entire ecosystem of biopharma production to optimize the process, without the biopharma manufacturer having to build a unique database – a truly smarter path into the future.

Leveraging SmartScience digital services expands product reach to global scale, creating new opportunities for valuable raw materials and goods to get to manufacturers – so vital therapies and treatments get to market sooner.